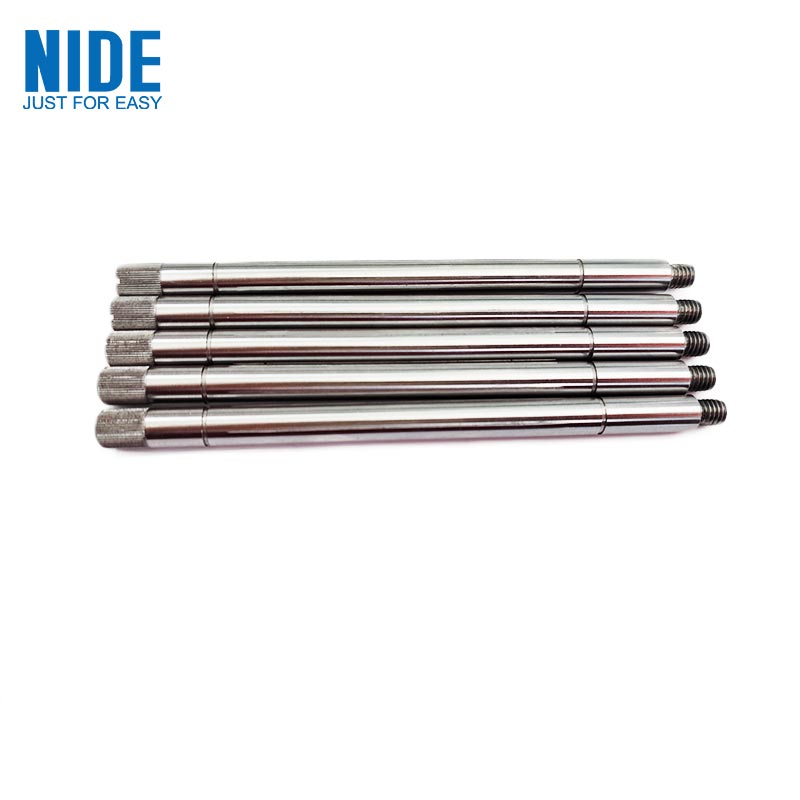

Chikafu Musanganiswa Motor Shafts Linear Shaft

Send Inquiry

Chikafu Musanganiswa Motor Shafts Linear Shaft

Yedu mota shafts ine hunhu hwekusimba kwepamusoro, yakakwirira chaiyo zvinodiwa, yakanaka kupfeka kuramba, yakanaka corrosion kuramba uye yakanaka kugadzirisa kuita kuti ive nechokwadi chekuita uye hupenyu hwesevhisi yemota.

Kugadzirwa kwemusanganisi mota shaft inoda kunyatso kudzora zvinodikanwa zvezvinhu, kugadzirisa tekinoroji uye mhando kuti ive nechokwadi chekuti mhando nekuita kweshaft zvinosangana nezvinodiwa zvekushandisa. Kazhinji funga zvinotevera zvinhu:

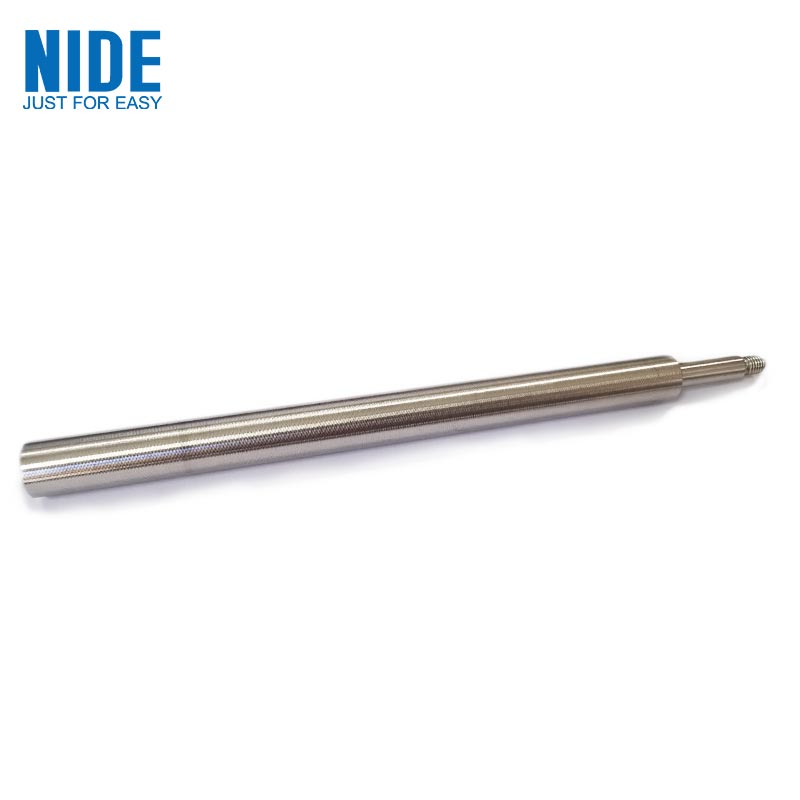

1. Kusarudzwa kwezvinhu: Iyo shaft shaft inowanzogadzirwa nepamusoro-simba alloy simbi kana simbi isina tsvina. Sarudzo yezvinhu inoda kutariswa zvinoenderana nezvinhu zvakaita senharaunda umo musanganiswa unoshandiswa, mutoro, uye saizi yeshaft.

2. Shaft processing tekinoroji: Iyo tekinoroji yekugadzirisa yemota shaft inowanzobatanidza akawanda malink akadai sekutendeuka, kugaya, uye kuchera. Izvi zvinongedzo zvinoda kunyatso kudzora kurongeka kwemuchina kuti ive nechokwadi chekuti dhayamita, kureba, kutenderera uye mamwe mativi e shaft anosangana nezvinodiwa.

3. Kurapa kwepamusoro: Kuti uvandudze kunaka kwepamusoro uye hupenyu hwebasa remota shaft, kurapwa kwepamusoro kunowanzo kudiwa. Semuyenzaniso, sandblasting, polishing, electroplating uye dzimwe nzira zvinogona kushandiswa kurapa pamusoro shaft.

4. Gungano uye kuongorora: Mushure mokunge kugadzirwa kwe shaft kwapera, kuungana uye kuongorora kunodiwawo. Paunenge uchiunganidza, kutarisisa kunofanirwa kubhadharwa kune yekumisikidza uye kukwana kweshaft kuti uve nechokwadi chekuti shaft inogona kuiswa nenzira kwayo musanganiswa. Munguva yekuongorora, zvinodikanwa kuita ongororo pazviyero, kuomarara, uye axial runout kuona kuti mhando yeshaft inosangana nezvinodiwa.

Chigadzirwa Parameter (Kutsanangurwa)

|

Simbi isina ngura |

C |

St |

Mn |

P |

S |

In |

Cr |

Mo |

Cu |

|

SUS303 |

≤0.15 |

≤1 |

≤2 |

≤0.2 |

≥0.15 |

8~10 |

17-19 |

≤0.6 |

|

|

SUS303CU |

≤0.08 |

≤1 |

≤2.5 |

≤0.15 |

≥0.1 |

6~10 |

17-19 |

≤0.6 |

2.5~4 |

|

SUS304 |

≤0.08 |

≤1 |

≤2 |

≤0.04 |

≤0.03 |

8~10.5 |

18~20 |

||

|

SUS420J2 |

0.26~0.40 |

≤1 |

≤1 |

≤0.04 |

≤0.03 |

<0.6 |

12~14 |

||

|

SUS420F |

0.26~0.40 |

>0.15 |

≤1.25 |

≤0.06 |

≥0.15 |

<0.6 |

12~14 |

Product Details